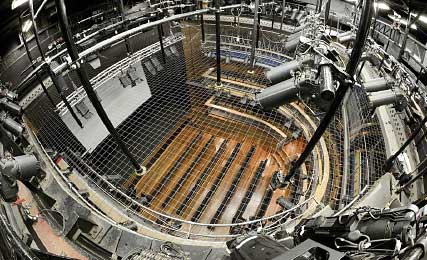

Arrange a visit

See Cablenet for yourself! We'd be happy to arrange for you to visit one of our existing tension wire grid installations, accompanied by one of our specialists.

Arrange a visitOnline estimator

We appreciate that all venues are unique and that design requirements can also be very different, but to help estimate budget for a Cablenet tension wire grid, we've created a simple cost estimator.

Open cost estimatorPROJECT TIMELINE

Our design, development and installation processes are structured to ensure that every stage of your experience of working with Slingco is handed in an efficient and professional manner

Find out more